Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: WBS-4

Brand: Winiber

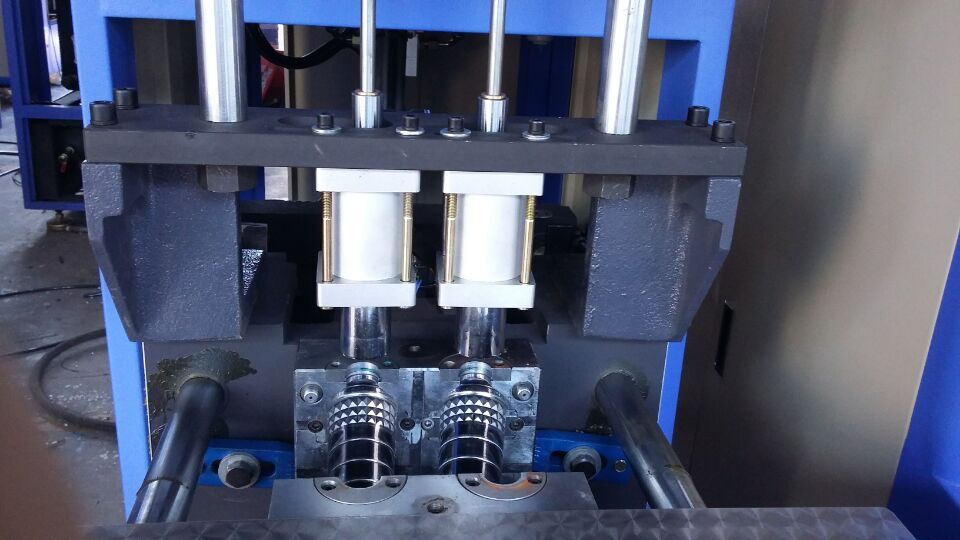

Type: Special Structure of Blow Molding Machine

Raw Material: PET

Making Method of Parison: Stretch Blow

Automation: Non-Automatic

Computerized: Computerized

Certification: CE

Packaging: Wooden Box

Productivity: 1800BPH

Transportation: Ocean

Place of Origin: China

Supply Ability: 40sets/Month

Port: NINGBO,SHANGHAI

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW

Semi automatic bottle heater blower machine adopts direct pressure, icrocomputer control, two step blowing bottle. The main blow tube blank PET mineral water bottles, beverage bottles, edible oil bottles, pharmaceutical plastic bottles, pesticide bottles, cosmetic bottles, etc.

The gas path is designed to separate the gas and blowing, adopting low pressure(0.4-0.8Mpa) mould clamping, mould locking, sealing, stretching and high pressure(3-3.5Mpa) blowing form, and the gas-liquid locking structure, to not only ensure the clamping and locking action smoothly, also ensure the safety of mould and blowing quality, as a result can save the bottle perform material.

| ITEM | UNIT | WBS-4 | |

| PRODUCT | Theoretical output | Pcs/hr | 1800 |

| Max. Volume | L | 3.0 | |

| Max. Height | MM | 360 | |

| Max. Diameter | MM | 105 | |

| MOLDING | Number of Cavities | / | 2 |

| Mould Plate Dimension(L*H) | MM | 490*405 | |

| Mould Thickness | MM | 220 | |

| Mould Opening Stroke | MM | 180 | |

| ELECTRICAL | Power | | 220-380V/50-60HZ |

| Total Power | KW | 21 | |

| Heating Power | KW | 20 | |

| MACHINE | Main Body Dimension(L*W*H) | M | 1.5×0.65×2.0 |

| Main Body Weight | KG | 550 | |

| Pre-heater(L*W*H) | M | 1.8×0.60×1.4 | |

| Pre-heater Weight | KG | 350 | |

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, Pet Preform Mould, Bottle Blowing Machine, Water Treatment system, Filling Machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also your share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, also USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Product Categories : Bottle Blowing Machine > Semi-automatic Bottle Blowing Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.